“I’m used to small data loggers. What are all of these sensor technologies and why should I care?”

You’ve heard RFID is cheap. You’ve heard NFC is what’s used by Apple. You’ve wondered about Bluetooth — where did that name come from, anyway? — and you’re hearing about cellular sensors. What’s the difference between these technologies and how do they help you reduce cost, waste and risk?

Don’t have time to research all of these technologies, but you’re wondering what they’re all about? This quick update should help you tell the difference — and understand the value, and limitations, of each.

RFID

Did you ever find one of those small plastic rectangles inside a DVD case? Ever used a contactless credit card in the checkout lane?Then you’ve been exposed to RFID sensor technologies. RFID (Radio-Frequency Identification) is a technology that uses radio waves to identify and track objects. RFID tags are small chips that can be attached to objects and contain a unique identification number. RFID readers can be used to read the data stored on these tags, and the technology is often used in applications such as supply chain management, inventory tracking, and access control.

There are a number of benefits to RFID technology over NFC or Bluetooth sensors.

First, range. RFID technology has a longer range than NFC and Bluetooth, which means that RFID tags can be read from further away. This can be useful in applications where it is not practical to bring the reader or the tagged object close together.

Second, cost: RFID tags are generally less expensive than NFC tags, which makes RFID technology more cost-effective for applications that require a large number of tags. Also, RFID tags are cheap because they contain no power supply – just a printed circuit that activates and takes a reading when exposed to wireless power. They are exposed to that power when they come within range of an RFID reader, wand, portal, or arch.

Data capacity: RFID tags can store more data than NFC tags, which makes RFID technology more suitable for applications that require a lot of data to be stored on the tag.

Durability: RFID tags are generally more durable than NFC tags, which makes them more suitable for use in harsh environments or for applications where the tags will be subjected to physical wear and tear. They can tolerate wet environments without worries of short-circuited electronics.

Security: RFID technology can offer a higher level of security than NFC and Bluetooth, as RFID tags can be encrypted and locked to prevent unauthorized access to the data stored on the tag.

Why we don’t recommend RFID for food tracking

The primary issue with RFID is power. Sensors need regular, continuous power if they are to take regular readings of temperature, humidity, etc. A lot can happen to cold chain products in between manual readings. So generally, RFID doesn’t give us consistent, automated temperature readings.

Secondly, RFID tags typically have very limited capabilities. Most used for food tracking only measure temperature, and not location or any other environmental conditions.

Finally, these tags don’t report location.

NFC

If you’ve ever used Apple Pay or Google Pay on your phone, tapping it on a cashier’s handheld reader, you’ve used NFC technologies. NFC (Near Field Communication) is a short-range wireless technology that allows for the exchange of data between devices. NFC tags are similar to RFID tags, but they operate at a shorter range and are often used for contactless payments and other applications that require a close proximity between the devices.

NFC tags have become more ubiquitous over the last few years and are compatible with a wide range of devices, including smartphones, tablets, and laptops, which makes it easy to use and accessible to a large number of people.

While these tags require batteries, they’re very stingy with their electrical needs, which is why it’s often used in wearable devices.

The downside of NFC for food tracking

NFC requires close contact (a few inches) between tag and reader. While powered tags can gather regular, consistent temperature and humidity readings, they require warehouse or shipping personnel to tap phones or readers against the tags. This manual effort adds to the time required by your teams to take measurements. So if you want a less laborious experience, NFC tech is out.

Bluetooth

If you’ve ever used wireless headphones or paired your phone to your car, you’re probably quite familiar with Bluetooth! Bluetooth is a wireless technology that allows devices to communicate with each other over short distances. Bluetooth devices use radio waves to communicate, and they can be used for a wide range of applications, including connecting wireless headphones to a phone, transferring files between devices, and connecting a keyboard to a computer.

For awhile, Bluetooth was seen as the cool-kid sensor technology. First, being battery powered, Bluetooth tags can take regular readings, ensuring consistent cold chain compliance. The tags are also small and cheap, with a range similar to that of devices in your house. If the tag is within 30 feet (10m) or so of a cell phone or other Bluetooth reader, this technology can make regular reports about temperature and humidity.

Why we don’t use Bluetooth

Bluetooth is a great technology, but — it has it’s downsides. Cue sad trombone sound.

First, you have to pair devices. Anyone who’s struggled with pairing headphones or a wireless speaker knows that this can be a time-consuming and irritating task. Imagine doing this for hundreds of sensors daily. Now imagine trying to integrate this task into your shipping department’s workflow! Hard pass.

You’ll also need a Bluetooth-compatible gateway, which connects these sensors to the Internet over a cellular or WiFi connection. Without that gateway, the sensors have no way to report that data back to you in an easy, automated fashion.

What are these sexy new “smart containers”?

One of the coolest technologies being used for shipping perishables are Smart Containers. These are usually refrigerated shipping containers that have on-board temperature and humidity sensors. These containers often connect to ship-board infrastructure when at sea, or via cellular when on land.

If your shipment is going to stay in one container from origin all the way to its final destination, these containers are great. You’ll know whether or not your product was kept cold-chain complaint the entire trip.

Also, if you ship primarily via ocean, both CMA-CGM and Maersk have visibility systems these containers report into. So you’ll have near-real-time ship position and container conditions.

Downsides to smart containers

But — and this is a really big but — what if your shipment gets cross-docked? What if it gets offloaded from the container into a cold storage warehouse for six months? You’ll lose that wonderful visibility. You won’t see what happened end-to-end. And someone in your back office will have ot work late to gather up that information from multiple sources.

And – these are super-pricey containers! You’re going to be paying for that expensive infrastructure, built into that unit and onboard the ship. They’ve gotta pay for that somehow. Chances are it’s a lot higher rate than what you’d pay with us!

Finally, our choice for sensor technology: portable cellular

Ever used a GPS tracker in your car? Then you’ve used a cellular sensing device.

Cellular sensors, obviously, are sensors that use cellular networks to transmit data. These sensors are equipped with a cellular modem that gives that device an IP address (connecting it to the Internet of Things) and allows the device to connect to a mobile network and transmit data to a cloud platform. Cellular sensors can be used to monitor and collect data from remote locations, say, from within reefer containers or cold storage facilities. They’re often used in applications such as environmental monitoring, asset tracking, and security.

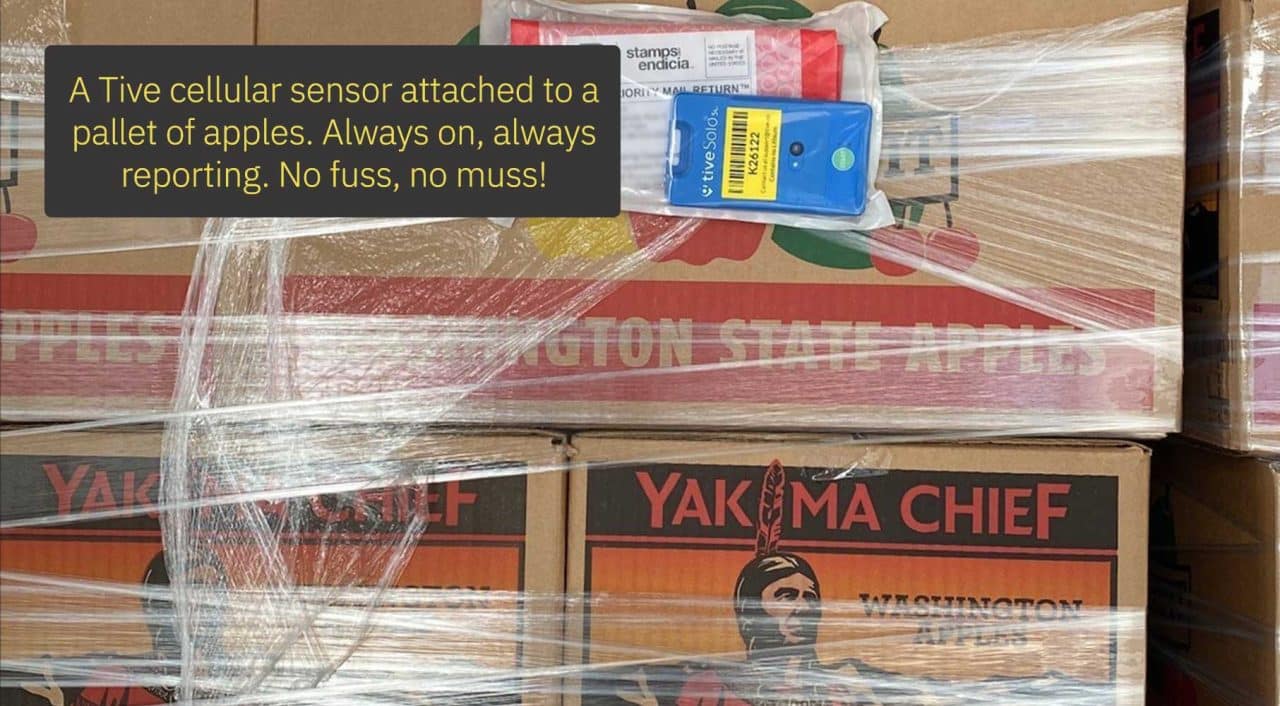

One of the main advantages of cellular sensors is that they can transmit data from virtually anywhere, as long as there is a cellular network coverage. The cellular devices we use, supplied by Tive, have global connectivity over vast swathes of the globe. This makes them ideal for reporting location and conditions regardless of where they are. Cellular sensors are also relatively easy to install and maintain, as they do not require any specialized infrastructure or workflow, such as connecting to a Wi-Fi network or a dedicated communication system. Simply stick ’em on a pallet, press the On button, and enter the sensor number in our platform.

While most cellular devices require SIM cards, which can add a monthly expense, our customers won’t need to worry about data plans. That’s all covered in our per-shipment fee.

This is also the best approach for loads that will be cross-docked. When placed on the pallet, the shipment can be tracked no matter how many times it changes hands or where it’s stored.

The primary issue that dissuades people from trying cellular sensors is the cost. These devices are more expensive than a simple data logger — and most folks are used to paying between $8-20 for a logger. Also, cellular sensors drink up power, so you may need to recharge a sensor if it’s low on juice.

But that cheap logger won’t give you real-time visibility. Won’t report its location. Won’t give you humidity, shock or light readings. And you’ll have to take time to download the information from it — if you get it back, that is.

In summary, we chose cellular sensors for the Transparent Path platform because:

- You don’t lose visibility due to cross-docking or storage.

- You’re not paying for expensive infrastructure, in the container or on a ship.

- You get regular, consistent readings reported back to your dashboard from anywhere*.

- You can see exactly where your shipment is, on a map.

- The light sensor shows when the container door was opened, and for how long.

- The sensor reports its battery levels so you can see when it needs recharging.

- The shock sensor will show you if the loads were handled roughly, potentially damaging your product.

- No one needs to wand or tap or scan a sensor.

- No one needs to ask for a data logger back and then download the information manually.

Questions?

We hope you’ve found this guide helpful. If so, please share it with others in your organization. And if you’d like more information or a demonstration of our low-drama, high-traceability devices and platform, schedule some time with your Transparent Path account lead today.

ABOUT THE AUTHOR

Eric Weaver is one of the biggest geeks you’ll ever meet. The son of an aerospace technician, he’s been fascinated by beeping devices with blinky lights since he was a toddler. He’s constantly coming up with crazy ideas for sensors, while CTO Sunil Koduri acts as the voice of reason.

May 2, 2021

(*) There are a few places in the continental US, here and there, where cellular coverage is spotty or non-existent. Fortunately, cell coverage is usually only about a half-hour away.

You must be logged in to post a comment.